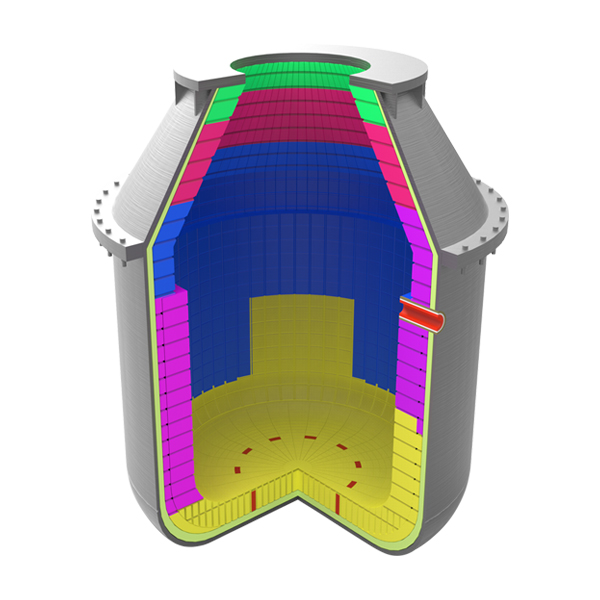

Overall contract for refractories of Convertor

Considered to be the heart of a steel shop, the Basic Oxygen Furnace (BOF) is a very complex equipment in terms of operation conditions, making it crucial for refractory suppliers to understand all the aspects related to it. Our BOF specialists are capable of delivering the solution that maximize your benefits by enhancing metallic efficiency and reducing refractory specific consumption.

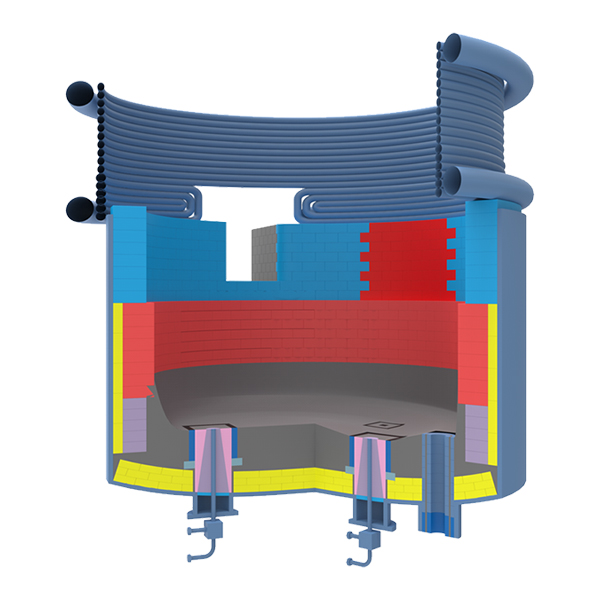

Overall contract for refractories of EAF

The electric arc furnace is essential for the re-processing of steel scrap, and this very aggressive process requires a large quantity of high quality refractories. Bricks and monolithics are made with carefully selected raw materials and controlled processes, to ensure the resistance and safety of its solutions.

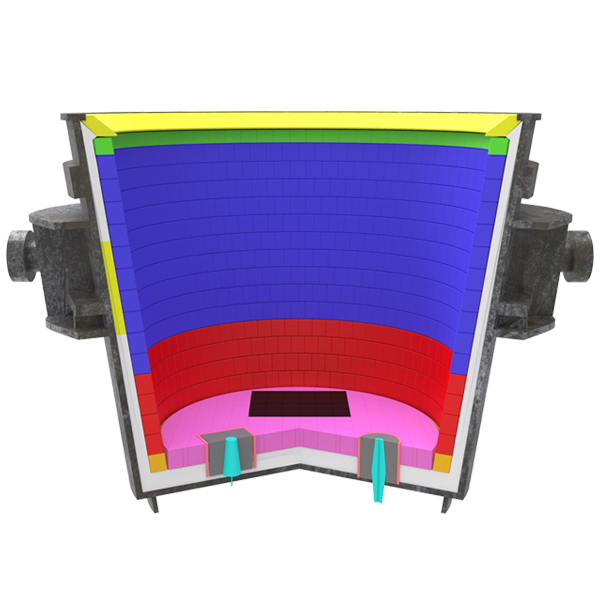

Overall contract for refractories of Ladle

The most versatile vessel in a steel shop, the steel ladle has an increasing importance due to the modern requirements of secondary refining processes. Also known to be the equipment that consumes the biggest amount of refractories in a steel shop, its optimized design is essential for cost reduction, energy management and steel quality. Our solutions not only withstand the most aggressive conditions but also are tailor made to reach the specific needs of each customer.

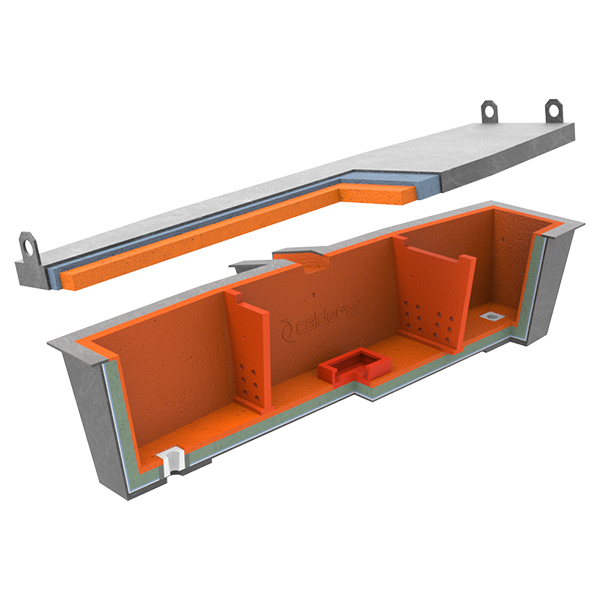

Overall contract for refractories of Tundish

Tundish in the steelmaking circuitry, like BOF/EAF and ladles, plays a pivotal role in determining plant performance and steel quality. Thus, beyond its traditional role as a buffer vessel, a steelmaking tundish is currently designed and operated to ensure maximum yield, superior cleanliness, negligible energy and materials losses and longer life. Naturally therefore, modern day steelmakers are emphasizing tundish management and practice.